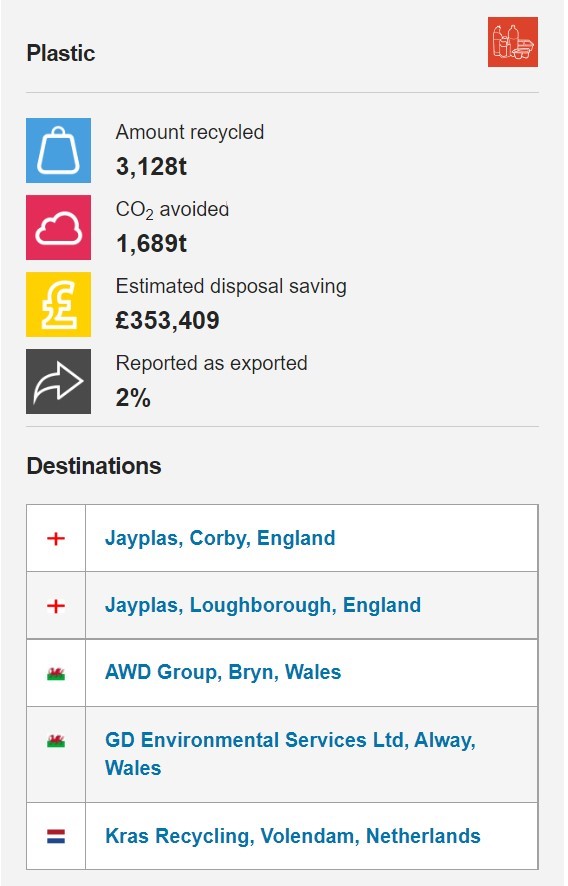

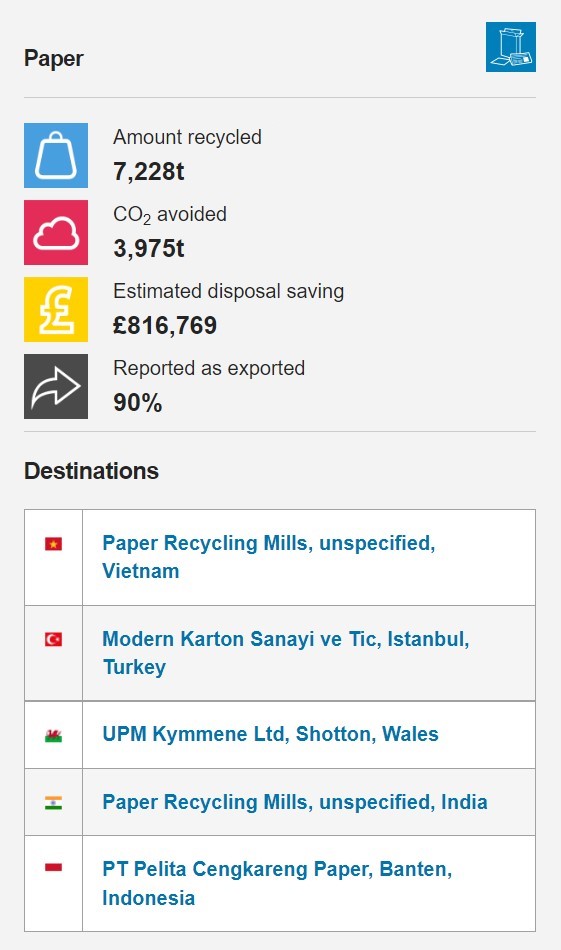

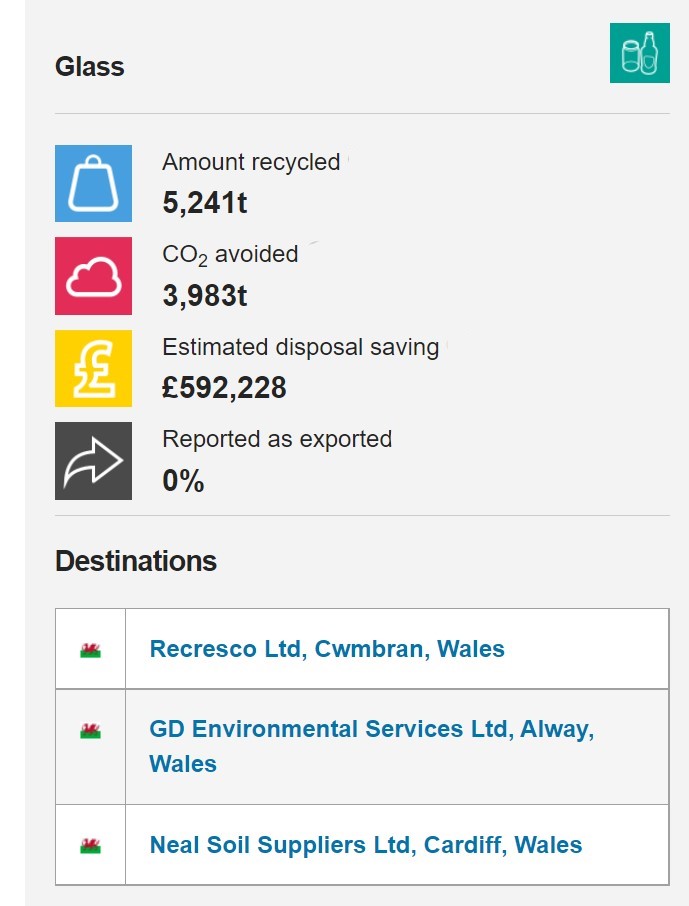

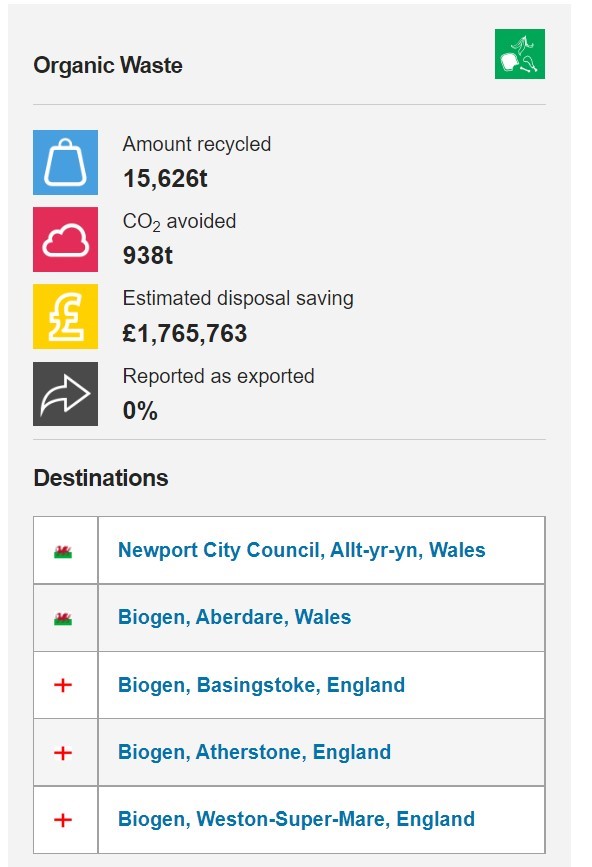

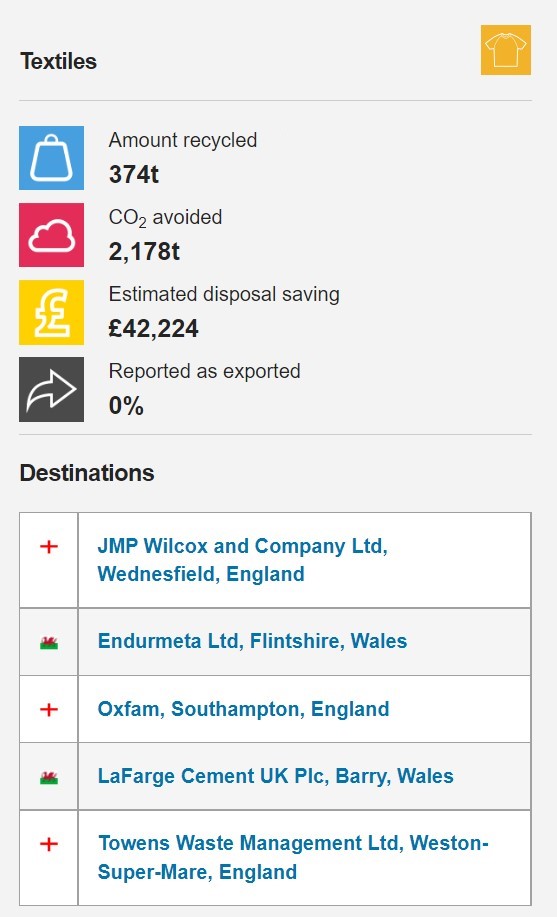

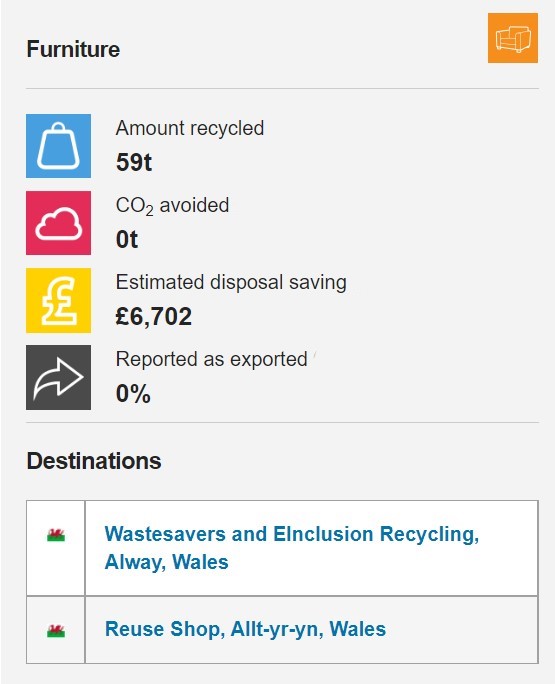

At Wastesavers we send your materials to the companies listed.

These are often multi-national companies with global markets.

They sell their finished recycled products around the world.

As a result plastic, for example, will be made into pellets here in the UK, but those pellets may be exported.